The Essential Guide to Self-Retracting Lifelines

Posted by info@customdigitalsolutions.co BigCommerce on Sep 5th 2024

The Essential Guide to Self-Retracting Lifelines

Protecting your team from fall risks without restricting productivity is a delicate balance. When your workers need the ability to move around freely in worksites with fall hazards, the self-retracting lifeline is a great addition to your fall protection system. Useful for a variety of applications, these vertical connectors offer both flexibility and security. With the right care and use, self-retracting lifelines can empower your workers to do excellent work without threatening their safety.

Key Takeaways

- Discover how self-retracting lifelines work and how they protect users from workplace falls

- Learn which situations require SRLs and when you should use an energy absorbing lanyard (EAL) instead

- Get a step-by-step guide to choosing the ideal self-retracting lifeline for your application and workplace needs

- Create proper inspection and maintenance processes with our detailed tips

What is a Self-Retracting Lifeline?

Self-retracting lifelines (SRL) include two major components, a lanyard and a housing unit, also called a self-retracting device (SRD). When you pull out and release the lanyard, it retracts itself into the housing unit, the feature that gives it its name.

If a worker falls while using an SRL, the sharp tug on the lifeline engages an automatic braking system inside the housing unit and restricts the falling distance to only a few inches. As long as the tension is maintained, it won’t release any more of the lifeline, holding the worker in place until they are rescued.

It helps to think about a self-retracting lifeline like a seatbelt, which extends and retracts as needed, but locks when tugged with sudden force. This design not only prevents falls but limits the amount of force placed on the worker’s body if one does occur. It also minimizes the potential injuries and dangers workers face on the job.

In the industry, this piece of equipment has many names. Along with self-retracting lifelines, you may hear them called yo-yos, blocks, devices, retractables, retractable lanyards, and automatic fall arrest devices.

What are the Differences Between Many of the Common SRLs?

The retractors we use today have evolved considerably from their early forms. In the early 20th century, workers used simple lanyards to stay connected to the structures they were working on. Workers and employers lacked connectors that could both enable workplace mobility and effectively protect against falls.

An automatic braking system was first added to connectors in 1963, using a disk block to stop lifeline payout during a fall. In 2002, a new design added teeth and pawls to improve the braking system. If the lifeline suddenly started paying out too quickly, the pawls and teeth would engage to halt the lifeline securely. Self-retracting lifelines continue to feature this design today.

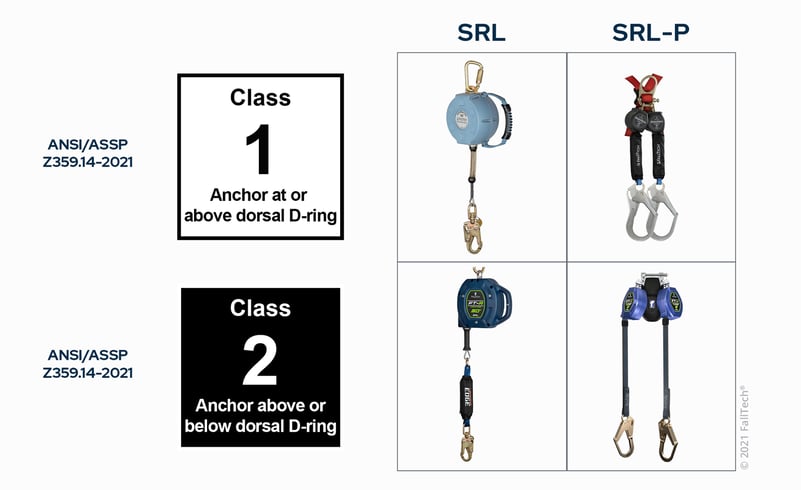

As technology advanced, regulations did too. In 2012, ANSI released the Z359.14-2012 standard, which outlined proper use, maintenance, and performance requirements. It also created two classes for self-retracting lifelines, Class A and Class B.

(On February 1, 2023, Class A and Class B will become Class 1 and Class 2)

Types of Self-Retracting Lifelines

Based on the ANSI Z359.14-2012 standard, you can generally sort the types of self-retracting lifelines into three main categories:

- SRLs - SRLs are standard retractable lifelines that can be used for a variety of applications and situations

- SRL-Rs - SRL-Rs are connectors made specifically for use in rescue situations

- SRL-LEs - SRL-LEs are lifelines designed to withstand contact with a leading edge

While you can use both SRL-R and SRL-LEs in situations that don’t require their specific functions, you can’t effectively use an SRL in a rescue scenario and you must never use an SRL over a leading edge.

You may also hear self-retracting lifelines referred to as “overhead” or “personal” SRLs. Overhead just means that the equipment is used with an overhead anchorage. You can use both SRLs and SRL-Rs with overhead anchorages, for example, but leading edge lifelines need lower anchorages.

Personal SRLs have a lighter, more compact version of the self-retracting device that connects directly to the dorsal D-ring. Their smaller size makes them easier to work with than the more common, larger form of SRLs. If you want to use personal SRLs, you can find both SRLs and SRL-LEs in this smaller size. Lifelines equipped with rescue capabilities, however, can not be used with personal SRDs.

We’ll go into each of these types of SRLs in more detail below.

Self-Retracting Lifelines: Overhead SRLs

Overhead self-retracting lifelines are only used for overhead anchorages. They offer extra length to increase your worker’s range of motion throughout the job site. As long as the lanyard is long enough, they can move around freely. That said, SRLs aren’t made to twist, so workers will need to be aware of how they move around the worksite to keep the lifeline straight.

Overhead self-retracting lifelines are only used for overhead anchorages. They offer extra length to increase your worker’s range of motion throughout the job site. As long as the lanyard is long enough, they can move around freely. That said, SRLs aren’t made to twist, so workers will need to be aware of how they move around the worksite to keep the lifeline straight.

It’s also critical to understand that overhead SRLs cannot be used over a leading edge. The materials and design are not made to withstand a fall over a leading edge, so the device may fail if used improperly.

Self-Retracting Lifelines: Personal SRLs

When using a personal SRL, workers carry the SRD directly on their backs. Because the lifeline is only 6-9 ft. in length, these connectors are ideal for conditions with low fall clearances, such

as home construction and roofing.

Though workers can’t go as far, they won’t have to worry about how they move while they work. The connection point on the SRD uses a swivel feature to keep the lifeline from twisting, simplifying movements. Unfortunately, some personal SRL designs are uncomfortable to carry, which may prompt some workers to work without them. When choosing one of these products, look for designs that limit back discomfort, such as our line of Duratech self-retracting lifelines.

Self-Retracting Lifelines: SRLs

These retractors are equipped with standard components, so they can be used for the most applications. They offer multiple anchorage options, giving you more flexibility when it comes to securing job sites.

If you don’t need to mitigate any specific hazards, this type is the

best choice. You can find these products with either overhead or personal SRL capabilities, increasing your workplace capabilities.

Self-Retracting Lifelines: Leading Edge SRLs

Many workplaces that present fall hazards also contain sharp edges. If a worker falls while using a standard lifeline and the connector is pulled taut against the sharp edge, it may damage or cut through the lanyard. Leading edge SRLs feature materials, such as cable or thick webbing, that can withstand this hazard.

You may also use SRL-LEs with foot-level anchorages. These low connections increase fall distance, fall forces, and the time it takes

for the braking system to engage. Calculating an accurate fall clearance and using well-maintained SRLs are critical in these situations.

Self-Retracting Lifelines: Rescue SRLs

After a fall, time is your greatest enemy. You need to react quickly to minimize injuries and prevent death. If your worker is stuck inside an enclosed space, however, it may take too long to reach them.

SRL-Rs include integral rescue capabilities, such as retrieval winches and brackets that can be attached to rescue tripods. When you can’t get down to your fallen worker, these features allow you to lift them quickly to safety. Since these lifelines are designed for rescue, however, they are not available as personal SRLs.

Components of a Self-Retracting Lifeline

A self-retracting lifeline consists of the lifeline, housing unit, and mechanism.

Lifelines are most commonly made from webbing, rope, or cable, which is typically either stainless or galvanized steel. These connectors can be as short as 6 ft. and as long as 195 ft., depending on the product.

The housing unit is contained in a hard outer casing that can range from a few inches to over a foot in size, depending on the length of the lifeline. Along with the coiled lifeline, this casing holds the braking system, mechanisms for smooth payout, and a retraction spring that keeps the lifeline taut when it moves in or out of the housing unit.

The mechanism is generally a snap hook, scaffold hook, or karabiner. These components feature a fall indicator to show when the equipment is no longer safe. If you see a red or orange strip above the clamp, it has likely been used in a fall and is no longer safe.

When Should You Use an SRL vs. an EAL?

Both self-retracting lifelines and energy absorbing lanyards offer adequate fall protection when used correctly. Because of the added range of motion, SRLs are the better choice when you have the ability to use an overhead anchorage. Retractables also arrest falls faster than EALs, minimizing the amount of force placed on the worker.

If you can’t use an overhead anchorage, however, energy absorbing lanyards are ideal for fall protection. They are also typically lighter and less expensive. If your work doesn’t allow for overhead tie-offs, such as with construction, EALs may be the better choice.

It’s important to remember that SRLs must never be used as a restraint device. If you need a connector to keep workers from reaching fall hazards, an EAL or other lanyard must be used.

Your competent person will determine which options are right for your work and job sites.

Choosing a Self-Retracting Lifeline

The first thing to consider when choosing your self-retracting lifeline is application. How do you plan on using it and what conditions will it be used in? This will help you determine which material is best. Cable is the most durable and common option, but webbing or rope lifelines may be more appropriate for your needs.

Next, confirm that the product meets ANSI Z359.14 and OSHA 1926.502 and 1910.66. Review the Declaration of Conformity and, if available, testing documentation. These devices may be the only protection your workers have against falls, so you have to find products that will perform perfectly. You will use this equipment nearly every day, so factory certifications and warranties are also important.

Evaluate the weight rating and ease of use to ensure it will help, not hamper, your team. Lastly, make sure it has the durability, dependability, and performance capabilities to protect your workers for as long as you need it to.

What to Look for in a Self-Retracting Lifeline

Since self-retracting lifelines are made for specific uses and situations, you must choose an SRL that works for your specific needs. Don’t let price or convenience drive this process. The consequences can, and very well may, be fatal if you make the wrong decision. Following the steps below and working closely with your competent person will help you find the right equipment.

1. Determine the Application

First, determine what you will use your self-retracting lifeline for. If your equipment is exposed to damaging conditions, take these needs into consideration. For employees that work with or near electricity, for example, you will need to choose a lifeline that protects against arc flash, such as one made of rope. You will also need to consider whether your work involves leading-edge or confined-space hazards. If so, choose the retractor with the capabilities you need, such as one with a winch or an option made from material strong enough to withstand contact with a sharp edge.

2. Identify Other Potential Hazards

After your competent person conducts their fall hazard analysis, review the hazards they found and where they are located. Next, identity your anchor points. If the workplace has a leading edge or requires a low, horizontal anchorage, you also have to calculate the swing fall. In these situations, workers that fall over an edge may swing when the lifeline’s brake engages. They may then collide with structures in the swing radius, causing new injuries.

For this step, you will also need to measure the safe work zone, the area where people can work without fall protection equipment. You will need to ensure that adequate anchor points are available outside of this zone.

3. Select your Self-Retracting Lifeline

Now you can focus on the less critical features of your SRLs. You should choose products that are longer than your minimum workplace requirements, but the exact length is up to you and your budget. Determine the weight capacity and other performance attributes that fit your needs.

You will also need to select the lifeline material. Cable is the most common SRL material and may be leading-edge-resistant depending on the product and cable thickness. Webbing is another common option, though it is expensive to repair. You can find SRL-LEs made of webbing, but the thickness required for the leading-edge rating makes them even more costly. Additional materials include polyester, Kevlar, Nomex, Dyneema, rope, and wire rope.

Once you know what you want from your lifeline, research the reputations of the manufacturers you find. Unfortunately, some disreputable companies will label products incorrectly, such as saying an SRL is leading-edge rated when it’s not. When these connectors are used in hazardous situations, they often fail, causing horrible accidents. Protect your workers by carefully reviewing the Declarations of Conformity and testing documentation for every product. You can also reach out to industry experts, such as our team, to get advice on choosing a safe self-retracting lifeline.

Note: As the new ANSI Z359.14-2021 standards take effect in August 2022, you may see labels change to reflect the new classifications. If you have any questions about SRL labeling or use, contact the manufacturer for clarification.

How To Inspect Your Self-Retracting Lifeline

Pre-use inspections are a must for self-retracting lifelines. Do not use a device that hasn’t passed inspection.

Start by inspecting the housing for cracks or damage. Do not open the casing unless you are authorized or trained to do so. You should be able to read the date of manufacture, serial number, manufacturer information, and warning information on the label. If not, remove the device from service.

You must put on gloves and mount the SRL before examining or using the lifeline. Never pull it out or let it retract while lying flat.

Slowly pull the cable out, looking for rust, cuts, pitting, corrosion, deterioration, modifications, or frayed, worn, or broken strands. Also check for crushed, jammed, or flattened strands, bulges in cable, gaps between strands, and heat damage, such as torch burns and electrical arc strikes. There shouldn’t be kinks, bird caging, core protrusion, or frozen wire rope. If you find any of these damages, remove the device from service.

For webbing, search for holes, tears, abrasions, discoloration, and fraying. Be sure to check both sides, pulling on the webbing as you go. Bend the lifeline into a U-shape to look for shiny spots or broken fibers. Take off your gloves and feel for hard spots. Make sure there isn’t any loose stitching and that the wear pad is present. If you find any holes or tears, remove the lifeline from service. If more than 10% of the lifeline has other damage, remove it from service.

There should be no cracks, bends, or discoloration on the carabiner. Test the lock to make sure it functions properly. The mechanism should move smoothly and lock by itself without catching when released.

Next, do a retraction and tension test. Pull out 50% of the lifeline, maintaining light tension on it, then let it retract. Repeat the test after pulling out 100% of the lifeline. Always keep light tension to keep the lifeline from retracting too quickly. All movement, in or out, should be smooth.

Finally, conduct a braking test. Give sharp, steady tugs to the lifeline to engage the brakes. Hold tension on the lifeline until the brakes are fully engaged. You shouldn’t see any slippage while the brakes are engaged. Release the lifeline and allow it to retract under light tension. It should retract smoothly. Repeat the test with the lifeline pulled out at different lengths. If you see any problems, remove the device from service.

For a more detailed inspection process, watch the video below: https://www.youtube.com/watch?v=f5AXLSR4fAw

How To Maintain Your Self-Retracting Lifeline

Lifeline maintenance is important because it keeps your equipment functional and ready to save lives when needed. While proper pre-use inspections can catch potential problems, caring for your equipment can help prevent issues from developing.

When an SRL is not in use, follow the manufacturer’s directions for storage methods. Generally, these devices should be kept somewhere cool and dry, away from moisture and direct sunlight.

Freewheeling is one of the most common causes of lifeline damage. When you completely release the lifeline rather than maintaining light tension as it retracts, the spring will coil too fast. Sometimes, this leaves some of the lifeline hanging out of housing since it didn’t coil tightly enough. Other times, the hook or karabiner hits the housing at high speeds once the cable retracts, engaging the lock mechanism. Someone then has to find a way to safely climb up to the housing unit to release the cable for future use. Freewheeling can also damage internal mechanisms and is known to destroy SRLs.

And, as mentioned, retractables are made for fall arrest, not restraint. Never use an SRL as a restraint device.

FAQs

How do self-retracting lifelines work?

Mechanically, SRLs function like a tape measure, but have an internal braking system that works like a seatbelt. You can pull the lifeline out and let it retract smoothly. If you give it a sharp tug, such as the sudden force applied during a fall, the braking system engages and locks the lifeline in place to minimize the freefall distance.

How does a self-retracting lifeline protect you if you fall?

The automatic braking system slows you down and limits the distance that you fall. You experience less force on your body and remain suspended until rescue.

How long are self-retracting lifelines good for? Do they expire?

As long as your SRLs pass inspection and meet manufacturer guidelines, they are safe to use. There is no shelf life or expiration date for a self-retracting lifeline.

What is the maximum length for a self-retracting lifeline?

Since self-retracting lifelines use an automated braking system, there is not a mandated maximum length. The maximum length available varies by manufacturer.

What is the maximum weight a self-retracting lifeline can support during a fall?

ANSI mandates that self-retracting lifelines must support as little as 130 lbs and as much as 310 lbs. Some SRLs have a higher capacity, but the maximum weight threshold will vary by manufacturer.

Why would a worker use a self-retracting lifeline when working from heights?

The automated braking system on an SRL reduces the fall distance and makes rescue easier. Its additional length and ease of movement also support many more applications than a lanyard. For these reasons, self-retracting lifelines are superior to other connectors and often the better choice.

Download The Essential Guide to SRLs White Paper

Why Choose FallTech for Your Self-Retracting Lifeline Needs

FallTech’s products meet the highest standards in quality, design, and safety. Manufactured in America and tested in our ISO-rated lab, our self-retracting lifelines and other fall protection equipment have never failed. We ensure that every product is ANSI and OSHA compliant, helping you build a strong safety program. Most importantly, you can confirm our performance claims against our Declaration of Conformity and testing documentation, all published online.

Buying fall protection from FallTech means gaining access to a comprehensive safety resource. As industry experts, our staff can help you stay up to date on industry changes and new compliance requirements. Our sales team is always available to answer questions and help you find the right systems. When the average set-up doesn’t meet your needs, we’ll work with you to find a solution that does.

At FallTech, we treat each customer’s safety concerns like our own. We are invested in every detail, giving you the time and attention you deserve. Our small chain of command means you get answers faster, empowering consistent safety for your team. From safety education to top-of-the-line fall protection equipment, FallTech is your solution.

Start enjoying improved workplace safety and flexibility by finding your self-retracting lifelines today.