The Ultimate Guide to Fall Protection

Posted by info@customdigitalsolutions.co BigCommerce on Feb 11th 2025

The Ultimate Guide to Fall Protection

In 2019, 615 people died when they fell from a height to a lower level while working. Another 48,040 had injuries severe enough to require time away from work.

If you operate in situations that place your workers at risky heights, using adequate fall protection isn’t just about compliance, it’s about protecting health and lives. When you know why these accidents happen and how to prevent them, you can create a workplace that makes safety a top priority.

KEY TAKEAWAYS

- Learn what causes falls, which industries require fall protection, and what you need to do to stay safe and compliant

- Explore the various types of fall protection to understand which options are best for your business

- Get tips for setting up fall arrest systems that will keep your workers safe in any circumstance

Part 1: Fall Protection 101

Fall protection includes a variety of methods that either prevent people from falling or protect against injury if someone does fall. The Operational Safety and Health Administration (OSHA) requires businesses to implement fall safety programs if workers operate above a specific height, including:

- Construction: 6 ft.

- General industrial: 4 ft.

- Long-shoring: 8 ft.

- Shipyards: 5 ft.

- Scaffolding: 10 ft.

When creating a fall safety program, businesses can choose from two types of fall protection, active and passive.

- Active Fall Protection - These controls require active participation from the person using them and specific gear, such as body harnesses, connectors, anchors, and more. Since users have to be involved in active protection systems, it’s critical that they understand how to use them. It’s also essential to keep the individual gear in good shape, so workers should always check their equipment before and after use.

- Passive Fall Protection - Passive systems, on the other hand, offer protection without the need for human input. Once installed, these controls stay in the same place. Common examples of passive systems include safety nets, guardrails, and barricades. Though just as important as active equipment, these controls are often considered a second line of defense in the event that active gear fails.

- Mechanical, Electrical, Plumbing (MEP) - Installing mechanical, electrical, and plumbing systems often means working on top of buildings, in tight spaces, on ladders, and other dangerous situations. These workers may also need fall protection equipment that prevents hazards such as arc flash or allows for easy mobility. Creating a system that meets all of these needs is essential for their safety.

- Metal Decking - Leading-edge hazards are the most prevalent concerns in metal decking. Unprotected floor openings, multi-level jobsites, and leading edges are other common hazards that metal decking workers face. A combination of active and passive fall protection systems is often used to keep workers safe from falls.

- Mining - Slips, trips, and falls are a serious risk in mining operations. Workers may experience unsteady footing and equipment malfunctions that put them at risk of falling from a height. Miners may also require fall protection that offers fall arrest and rescue capabilities, offering reliable safety in tight spaces, on ladders, and any other situations they might face.

- Oil & Gas - Mining and drilling involve dangerous work and circumstances for everyone involved. Workers should use full-body harnesses, lifelines, and anchors to both prevent and arrest falls, as well as passive equipment that improves their safety.

- Pulp & Paper - Paper-making factories rely on large machines, which in turn demand continual maintenance. As workers move around the facility and this equipment, they use harnesses, lanyards, and anchors to prevent falls and avoid injuries. Walkways and surfaces are often slippery in these plants, so using the right gear is essential.

- Roofing - Roofers face a work fatality rate that is more than 10 times greater than the national average for workplace fatalities, mostly caused by falls. Along with using the right anchors and lanyards for the jobsite, roofing companies must also implement equipment, plans, and procedures that encourage daily use. With these precautions, they can more effectively prevent falls and minimize the consequences when they occur.

- Scaffolding - Scaffolding presents unique fall protection challenges which are often overlooked or inadequately addressed. To maintain full workplace safety and regulatory compliance, companies have to carefully develop the right plan for every job that requires a scaffold. Common methods of fall hazard mitigation include body harnesses, lanyards, handrails, guardrails, and other active and passive methods.

- Silos & Towers - Farmers and agricultural workers deal with large equipment and tall structures, increasing their risk of falling. They are also affected by weather conditions more than some other industries. To avoid falling from silos, combines, or towers, agricultural workers should have access to a variety of active and passive systems that will both prevent and arrest falls.

- Steel & Foundry - Frequent inspections, maintenance, and repairs keep the ladle cranes in steel & foundry mills operating at their peak. When workers scale this large equipment to perform this work, however, they face numerous fall hazards. Using a combination of equipment and training, mills can reliably protect their workers from fall-related incidents.

- Steel Erection - When working in steel erection, workers face fall hazards such as narrow beams, leading edges, extended freefalls, dropped objects, low clearances, a lack of adequate overhead anchorages, and many more. Steel erectors need a strong fall protection plan to complete their work without facing the risks of fall-related accidents.

- Tower - Numerous industries utilize towers, such as telecommunications and energy. As workers scale these towers, they must climb hundreds of feet into the air. Protecting against falls means using equipment such as Y-leg lanyards and positioning lanyards, which allow workers to stay connected to the tower at all times as they climb.

- Warehousing - In a warehouse, workers may be operating from ladders, stairways, loading docks, stock pickers, tall equipment, or mezzanines. Many warehouses also set a fast pace, so workers need a fall protection system that will keep them safe if they take a wrong step. Common equipment includes guardrails, body harnesses, lanyards, and overhead anchorages to prevent swingfall.

- Window Washing - Window washers must move up and down tall buildings, using a combination of equipment to access windows that may be hundreds of feet above the ground. Typically, a window washing fall protection system will include roof anchors, body harnesses, support ropes, lanyards, a controlled descent device, and a seatboard.

Main Governing Bodies

Several governing bodies in the U.S. have created guidelines for proper fall protection implementation and use. The two most important bodies include OSHA and ANSI. OSHA is the official government agency that creates and enforces standards to ensure safe working conditions. ANSI, on the other hand, helps industries maintain consistent, voluntary standards set by the people involved in these industries. Fall protection equipment and practices may also be guided by standards set by the International Safety Equipment Association (ISEA) and Canada’s CSA.

Occupational Safety and Health Administration (OSHA)

OSHA was created to enforce workplace safety throughout the United States. It has the governmental authority to regulate the conditions every company creates and to cite those that don’t comply. To meet OSHA’s requirements for fall protection, organizations have to follow several regulations that create a safer work environment. Though they are separate organizations, OSHA will occasionally adopt ANSI standards to further improve workplace safety.

American National Standards Institute (ANSI)

As a private organization, ANSI can’t enforce or cite violations of any regulations. Instead, it works with its members to develop industry standards and accredit organizations that meet these standards. Since it works directly with people involved in fall protection, its standards are widely accepted and trusted as the best options. And, because these standards reflect in-the-field insights that OSHA can’t access, ANSI standards are sometimes made into law, as mentioned above.

Part 2: Types of Fall Protection Equip ment

Fall protection equipment is required for a variety of jobs, so the types of gear used varies as well. While some options are used to prevent injury after a fall, others are used to support workers who need hands-free suspension to complete their work.

When choosing equipment, it’s critical to understand what you need and why you need it. In this section, you’ll learn about the various types of fall protection gear, what they include, and how they can help protect your workers from falls.

This information will give you a better understanding of the right equipment for your organization, but you should also rely on your fall protection training and experts to guide your choices.

Fall Arrest

A fall arrest system is designed to protect users in the event of a fall. This gear is made to halt the person’s descent, distribute the force of the fall to minimize injury, and position them in a way that prevents further injury while waiting for rescue. The final holding position is also designed to make rescue as easy as possible.

The potential consequences of not using a fall arrest system are severe. Unless the user does fall, however, this equipment is only meant to be worn and not actively used. Although this might make you question its necessity, everyone who works at a height over six feet should use an adequate fall arrest system.

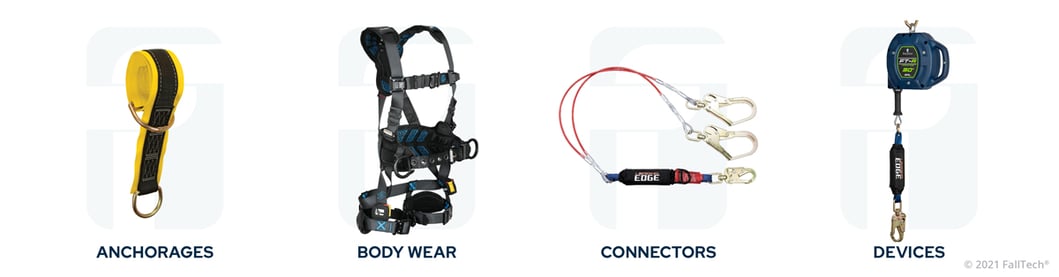

This type of equipment includes several components that work together to offer the best protection. An easy way to remember these pieces is to follow the ABCs of fall protection:

- Anchorage, including:

- Anchorage

- Anchorage connectors

- Body wear

- Connectors

Anchorage

OSHA defines an anchorage as a secure place of attachment for lanyards, lifelines, and deceleration devices. This point of attachment can be any variety of structures, such as columns, beams, or floors, that can adequately support the force of a fall from that structure. The rest of the fall arrest system depends on the anchorage point, so it is critical to choose the right structure.

In addition to the anchorage point, your equipment will also include an anchorage connector that connects the rest of the system to the anchoring structure. Depending on the type of anchorage point, you may use a D-bolt, hook or beam anchor, davit, or any other similarly secure device as an attachment.

Body Wear

This part of the fall arrest gear is worn by the person using it. Previously, body belts were accepted as adequate body support components. This equipment, however, doesn’t offer adequate fall protection and often causes further injury when arresting the fall, so it is no longer recommended.

Instead, you should use a full-body harness with your fall arrest equipment. These harnesses include straps that cross over your shoulders, around your waist, and around your legs and pelvis. This configuration distributes the force of a fall across the body to minimize the impact and chance of injury. It also uses carefully positioned D-rings or connectors to keep you in the best position for your health and rescue.

Connectors

This final piece of equipment connects the full-body harness to the anchorage connector. Since it is made to minimize the forces applied to the body when arresting the fall, most systems use an energy-absorbing connector. They may also use fall limiters or self-retracting lanyards to limit the falling distance. Common means of connection include rope grabs, energy-absorbing lanyards, self-retracting lanyards, fall limiters, and retrieval systems.

Positioning

Many industries include work that must be completed as you are leaning back at an odd angle while also keeping your hands free. Iron workers who are tying rebar for a new wall, for example, need to work up and down the wall with both hands available. In these situations, a work positioning system keeps them securely in place so they can move around as needed. This equipment is set up to ensure that you can only fall a maximum of two feet, but a fall arrest system should also be used for those working at heights above six feet.

These systems include:

- Anchorage - Workers are tethered to structures that can support them securely as they work.

- Body Wear - Depending on the circumstances, either a full-body harness or body belt can be used.

- Connectors - Common connectors include anchor bolts, carabiners, rebar assemblies, and trolleys.

Suspension

Some jobs, such as window washing, require workers to be suspended and able to move up and down. Also commonly used in the painting industry, suspension systems leave you hanging vertically with both hands free. Users can move around as needed to reach every part of their work surface.

Like positioning systems, suspension equipment is not designed to stop falls. You must also use a fall arrest system in conjunction with your suspension system to protect workers, particularly those working from a height greater than six feet.

Suspension system gear includes:

- Anchorage - Users are anchored to an adequate support structure that offers access to their work area.

- Body Wear - Full-body harnesses are the only acceptable form of body wear for suspension systems.

- Connectors - Vertical lifelines are the most common connectors used for these systems. You can also include lifelines with rope grabs, which work to decelerate and stop sudden descents, as backup options. Rope grabs are not, however, an alternative to a fall arrest system.

Retrieval

Like fall arrest systems, retrieval equipment should only be used in an emergency situation. These systems should be part of your fall protection program, which should also include procedures to follow after a fall to ensure quick rescues. This is especially important if fallen workers will be left in a position that makes rescue from above difficult. If your industry includes work conducted in confined spaces, such as manholes, retrieval systems are critical.

For a retrieval system, you should use:

- Anchorage - Your anchorage should use a structure that can both support the worker and offer a good position for rescue, if needed. You should also use a davit or tripod as your anchorage connector.

- Body Wear - Retrieval systems must include full-body harnesses.

- Connectors - Self-retracting lifelines or lifelines equipped with tools that workers can use to assist in their recovery are ideal.

When Should You Replace Fall Protection Equipment?

No matter what type of fall protection equipment you are using, it could be the difference between safety and injury or death. With so much depending on these systems, in-depth inspections should occur both before and after every use. A competent person should also inspect all of your fall protection gear at least every six months.

Your inspections should follow manufacturer recommendations and cover every piece of equipment, including:

Anchorage - Your anchor points should be free of all damage. Check the stitching for loose or broken stitches. Webbing shouldn’t show excessive wear, cuts, holes, burns, UV damage, or chemical damage. Inspect the hardware for damage, rust, corrosion, missing rivets, cracks, and deformities. You should also check the functionality of latches, springs, and other components. Use your anchorage inspection form to avoid overlooking any issues.

- Body Wear - Check every inch of your straps and belts for fraying, pulled stitches, cuts, and other damage. Your D-rings and wear pads should be free of cracks, breaks, rough edges, and distortions. Buckles should also retain their shape and unimpeded motion. If you notice anything out of the ordinary, note it on your harness inspection form and report it to your company’s qualified person.

- Connectors - Be sure to check your lifelines and lanyards from end-to-end, rotating to inspect every inch. Look for unusual patterns, cuts, fraying, worn or fuzzy fibers, spliced ends, and any other damage. Depending on the material, you may need to stretch the connector over a rounded service to fully evaluate the equipment. Report any problems with your lifeline inspection form.

If stored properly and inspected regularly, your gear should remain in good condition. As soon as you see any of the damage indicators mentioned above or on your inspection form, however, the equipment must be evaluated further and either repaired or replaced.

Most importantly, every piece of equipment involved in arresting a fall must be replaced immediately. This gear has now sustained irreparable damage and can no longer protect your workers.

Part 3: Setting Up Fall Arrest Systems

Your fall protection equipment is only as good as the people using it. Even the best fall arrest systems will fail if they are not used and set up properly. Some of the dangers posed by improper equipment use include:

- Failure to Arrest the Fall - If your anchorage isn’t set up well or you use a structure that can’t support the person’s weight, a fall may still result in injury or death.

- Suspension Trauma - While most people are aware of the potential injuries that result from a fall, few know that workers are in immediate danger following a fall arrest. Right after a fall, the person is often left hanging by their body harness until they are rescued. This position cuts off circulation to the legs by compressing the femoral arteries. In just minutes, the trapped blood can pool and turn toxic. If rescue doesn’t happen quickly, the worker may lose consciousness, sustain permanent damage to their internal organs, or even die.

- Equipment-Caused Injuries - If you use body belts rather than full-body harnesses or ill-fitting gear, your system may cause injury when it arrests the fall.

Avoid these injuries by using your fall protection equipment in the methods provided by the manufacturer and your competent person’s training. You can use the steps below as a starting point for your system, though we recommend that you rely on official directions.

1. Training

OSHA requires that every jobsite that needs fall protection equipment is supervised by a “competent person” or “qualified person.” This person is an employee who has received extensive training on the dangers of falls and the use of safety equipment. Your organization’s competent person is responsible for ensuring safety conditions are met on each jobsite and for training the rest of your employees.

Before anyone on your team uses fall protection gear or works on job sites with fall hazards, they need to undergo live, hands-on training. Your competent person will teach every worker about the purpose and limits of each piece of your systems. They will also show everyone how to use them properly.

By the end of the training sessions, every worker should have site-specific knowledge such as:

- Each part of their personal protective equipment and how they all work

- The right tools to use in specific situations

- How to correctly don their gear

- How to inspect their gear

- How to evaluate the workplace, identify dangers, and eliminate hazards

- Choosing appropriate anchorage points

- Ways to understand and reduce free fall distances and arresting force

- The limitations, requirements, and capabilities of their fall protection equipment

- What could happen if they ignore manufacturer instructions and training procedures

2. Planning

Your qualified person is also responsible for creating a fall protection plan. This plan should include which systems to use for each specific situation your workers may encounter. They should also guide the organization in acquiring the various types of passive and active protection systems needed for the type of work you do.

For full safety, your fall protection plan should include steps to follow in the event of a fall. Though some actions, such as calling 911, seem obvious, your team may not remember what to do in the moment without pre-planning. Include steps such as evaluating the situation, determining the best approach for rescue, getting help, and preventing similar accidents. The more you can prepare your team, the faster they can react.

3. Inspection

As mentioned above, inspection is an essential part of using fall protection gear. Find or create inspection forms that ensure every piece of equipment is fit for use. If anyone is unsure about the safety of their gear, that item should be set aside for further inspection and repair. Emphasize the importance of thorough inspections to prevent issues that could have easily been avoided.

These evaluations are particularly critical if your workers share gear. Since you don’t know who had it or how they used it before you got it, take the time to confirm its readiness. And, no matter how well they inspected the equipment after their last use, remind workers that each evaluation has the power to save lives.

4. Installation

When you are satisfied that your systems meet safety standards, you can then implement them in your worksites. If possible, your competent person should be directly involved in the installation. If that isn’t an option, have them inspect job sites where fall protection is in place as often as possible.

During these inspections, qualified persons should be checking for two things:

- Correct Installation - Without proper inspections, the only time you will learn about faulty installations is when the equipment fails. The competent person should be checking everything from guardrails to safety nets to anchorage points to prevent this. Someone’s life may depend on these systems, so there is no room for error.

- Correct Use - Proper installation with incorrect use is still a recipe for failure. These inspections should examine how the equipment is used and what it is used for. If workers aren’t following manufacturer instructions and industry standards, these actions should be stopped immediately. Take care to ensure everyone is using gear that fits them properly, as well. Poorly fitted equipment can offer false confidence and end in grave injuries.

5. Maintenance

The better you maintain your fall protection systems, the more effective they will be. Follow your manufacturer instructions for storing your gear, taking care to protect it from sun exposure, moisture, heat, and chemicals. If your equipment collects dirt or debris during use, follow manufacturer recommendations for cleaning.

In the event of damaged equipment that is waiting for repairs, find a place to store it away from your working gear. You don’t want someone to grab and use faulty equipment by mistake.

Along with the personal inspections performed by employees before and after use, you should also schedule additional evaluations for your full range of equipment.

Conclusion

While you hope you’ll never need to use it, fall protection systems are essential for the safety and well-being of workers in numerous industries. Education, training, and planning will help you build a team that respects the dangers of the job and need for proper use of equipment. As you develop a fall protection program that prioritizes safety, you can focus on your work with confidence in your systems.